The difference between resistive screen and capacitive screen

Resistive screen: The full name is resistive touch screen, commonly known as "soft screen". It is divided into three layers in structure. The inner layer is glass and the outer layer is a thin film. The adjacent sides of the thin film and the glass are coated with ITO (Indium Tin Metal Oxide). ). Resistive screens can be divided into four-wire, five-wire, seven-wire or eight-wire touch screens. The difference between these categories is the difference in the bias voltage of the screen. The application of the resistive touch screen in the touch all-in-one machine, due to its one-point touch technology principle, makes the machine touch more accurate. At the same time, in the pixel configuration, it can support HDMI 4K video and video transcoding, and the display effect is more high-definition.

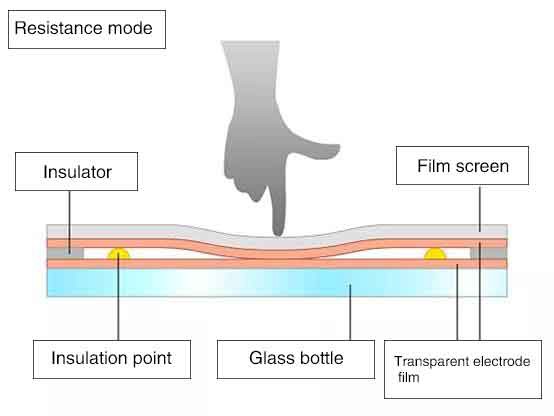

Working principle: Simply put, the resistive screen is actually a kind of sensor. When the resistive screen is operated, when the two layers of film and glass collide with each other, the current will have an impact. Based on the data between the calculated power and the current, the chip evaluates which position of the screen is compressed and reacts. It is precisely because the resistive screen is touch by force, so this principle causes the resistive screen to only touch one point, and it is difficult to achieve multi-point touch. This principle also makes resistive screens mostly used in harsh industrial use scenes where there is a lot of dust, large temperature differences, and operation with gloves.

Capacitive screen: The full name is capacitive touch screen, commonly known as "hard screen". It is a four-layer composite glass screen. The first layer is ITO to ensure the working environment. The second layer is glass and the third layer is also ITO coating. Used as a working surface; the fourth layer is a protective layer of silica glass. Many well-known, the main feature of the capacitive touch screen is that it can realize multi-point touch.

Working principle: Capacitive screens actually use human body current sensing to work, which can be understood as the need for touch media with bioelectricity to touch. In other words, the capacitive screen uses the lower layer to transmit signals to the upper layer. When the upper layer is contacted by the conductor, the lower layer can quickly receive the information and make calculations. Determine where the finger touches and react. It is precisely because of this that the capacitive screen can not only support multiple points at the same time, but also greatly improves the sensitivity of hand touch. Therefore, capacitive screens are mostly used in normal industrial application scenarios without special requirements.

In conclusion, when choosing a suitable industrial LCD screen and industrial touch screen, it needs to be decided according to the application environment of the product, the application population and the product market. The choice between capacitive touch screens and resistive touch screens is usually determined by aspects such as cost, accuracy, damage resistance, and environmental adaptability.